High quality 1.5L scale lab spray dryer equipment

Lab scale spray dryer is suitable for the production of in universities, research institutes and food and pharmaceutical chemical enterprises.

Model Number:

OLT-SD-1500Minimum Order Quantity:

1Capacity:

3.5KWSpeed:

30-2000ml/hVoltage:

108V-220V 50/60HZPower:

1 YearsWarranty:

Western Union, T/T, L/CDimension(L*W*H):

650*500*1550 ( mm )Packaging Details:

Export wooden packageDelivery Time:

6-8 day1 Various fields where the production of a free powder sample is required

2 OLT-SD-1500 has successfully processed samples in the following areas: beverage, flavours and colourings, milk and egg products, plant and vegetable extracts. pharmaceuticals, synthetics heat sensitive materials, palstics polymers and resins, perfumes, blood, ceramics and superconductors biochemicals, dyestuffs, soaps and detergents, foodstuffs, adehesives, oxides, textiles, bones, teeth and tooth amalgam and many others.

|

Model |

OLT-SD-1500 |

|

Max capacity |

1500-2000ml/h |

|

Temperature range of Inlet air |

30C -280C |

|

Temperature range of outlet air |

40C -120C |

|

Precision of temperature |

± 1 C |

|

Dryer time |

1.0-1.5 S |

|

Speed of squirmy pump |

30-2000ml/h, |

|

Consume of dryer air |

0-330m3 /h, max pressure: 686Pa |

|

Consume of spray air |

0-4.2m3 /h, spray pressure: 2-5bar |

|

Spray system |

2 liquid nozzles with standard 0.7mm jet options of 0.5/1.0/1.5/2.0/2.5mm |

|

Spray direction |

downwards co-current |

|

Power |

3.5KW 220V |

|

Dimensions |

650*500*1550 ( mm ) L * W* H |

1 Special for lab research, min 20-30ml liquid to finish one test

2 All borosiliscate glass for easy visual monitoring of process status

3 Spray chamber, cyclone separator, receiving talk are all made of borosilicate glass which can resist strong acid/alkali, high temperature, it can work in a no-pollution and stable enviroment

4 Easy to clean and very simple to assemble and break down

5 The air compressor is no oil and don't pollute compress air, the sound is low than 50db and following the GMP understands.

6 Inlet/outlet temperature is accurate controlled by PID.

7 The unit is self contained and supplied complete and ready for immediate operation

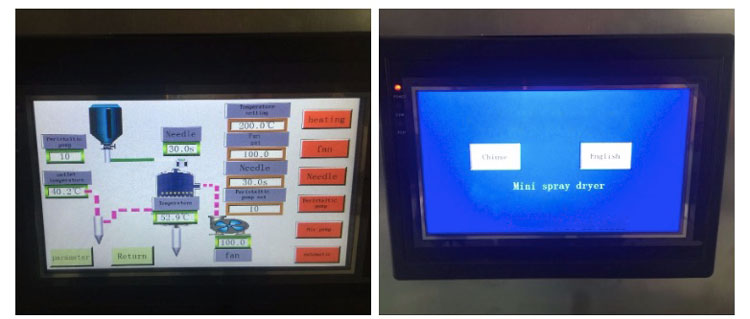

8 Using screed touchable face display operation, control temperature, airflow volume, air pressure, pump speed and de-blocker frequency

9 Product feeding with RS2559605 rotary pump, capacity is adjustable

10 Automatic de-blocking device prevents the nozzle from becoming blocked and varaably controlled

Packing and Shipping

Packing and Shipping

Ollital Technology would like to establish win-win business cooperation with distributors all over the world.

online service

online service +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529